Electric Motor Repair: Providing Longevity and Efficiency to Your Appliances

Electric motors are an essential part of most home and industrial appliances. They drive air conditioners, washing machines, refrigerators, and other electric appliances. However, electric motors can develop faults over time as a result of frequent usage, excessive heat, mechanical stress, or electrical faults. Consequently, replacing a malfunctioning electric motor can be costly. Therefore, electric motor repair is a cost-effective and more efficient method to improve appliance performance and prolong its life.

At HK Appliances Repair Dubai, we offer professional electric motor repair services. Our skilled technicians diagnose problems, fix faulty components, and get the motor running smoothly. In this guide, we will discuss the importance of electric motor maintenance, typical motor issues, the repair process, and why professional services are necessary.

What is Electric Motor Repair?

Understanding Electric Motor Functionality

Electric motors transform electrical energy into mechanical energy, energizing different appliances. Electric motors work through electromagnetic induction, in which electrical current produces a magnetic field that makes the rotor rotate. The primary parts of an Electric motor are the stator, rotor, bearings, windings, and cooling system. All these components are essential in making the motor run smoothly

How Electric Motor Repair Works

Electric motor repair entails fault diagnosis, replacement or fixing of faulty parts, and making the motor operate optimally. Moreover, properly maintained electric motors guarantee appliances operate at peak levels, conserving energy and avoiding sudden breakdowns.

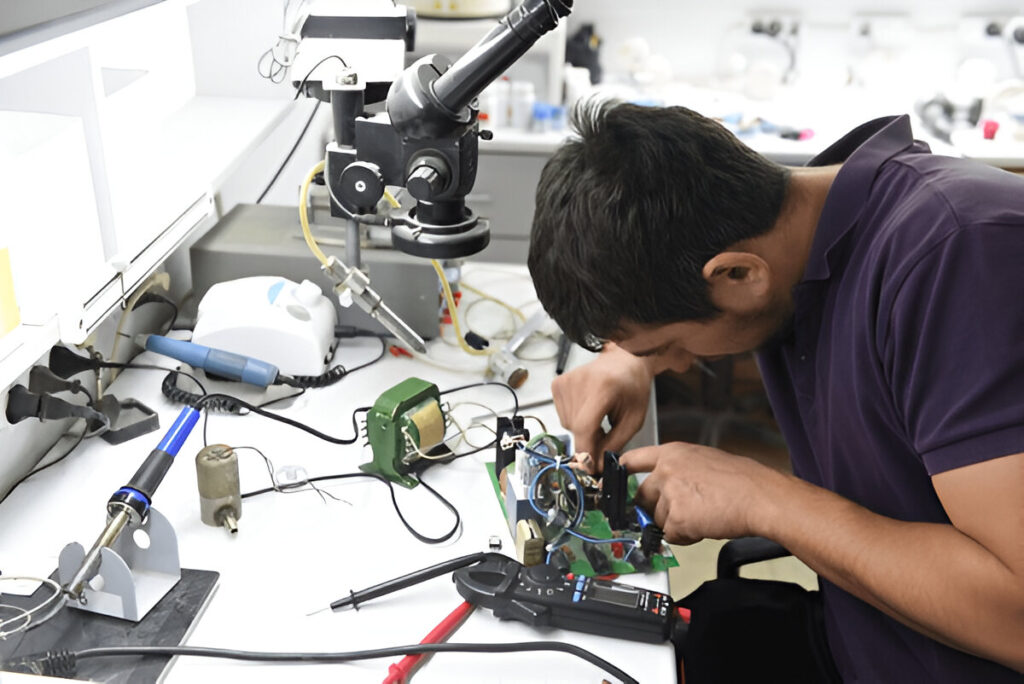

The repair process entails checking electrical connections, bearings, windings, and insulation for faults. In addition, trained experts employ specialized equipment to identify faults and return the motor to its original state.

Furthermore, neglecting small problems in an electric motor may result in a total breakdown, which requires expensive replacements. Therefore, repairing in time prevents this and ensures the motor runs smoothly.

Electric Motor Problems That Need Repair

Overheating Problems

High temperature degrades motor insulation, making it deteriorate over time. Consequently, this results in short circuits, decreased efficiency, and possible motor failure. Moreover, overloading, insufficient ventilation, and insulation damage all cause overheating. Therefore, proper airflow and avoidance of excessive loading can prevent it.

Bearing FailuresBearings

Bearings support the rotating shaft and reduce friction. However, over time, they wear out due to continuous use, leading to noise, vibration, and misalignment. If left unaddressed, damaged bearings can cause the motor to stop functioning. Therefore, regular lubrication and timely replacement prevent bearing-related issues.

Electrical Faults and Power Surges

Fluctuations in voltage, power surges, and poor wiring can spoil electric motors. As a result, electrical breakdowns lead to burnt windings, loose contacts, or capacitor breakdowns. Therefore, detecting and fixing these faults on time helps the motor run without interruption.

Unusual Noise and Vibrations

High noise from the motor is usually an indication of misalignment or internal damage. Additionally, strange vibrations suggest that worn-out parts should be replaced. Thus, fixing these faults early prevents further complications.

Motor Failure to Start

If the motor does not start or runs with reduced capacity, a faulty capacitor, wiring, or coil wear and tear could be the cause. Therefore, a comprehensive inspection determines the fault, enabling accurate electric motor repair.

The Electric Motor Repair Process

Step 1: Diagnosis and Testing

Our technicians perform a thorough examination with specialized tools to test voltage levels, insulation resistance, and wear on components. As a result, determining the cause of the issue guarantees proper and effective repairs.

Step 2: Disassembly and Cleaning

Once the problem is diagnosed, the motor is disassembled with care. Additionally, the accumulation of dirt, dust, and moisture can affect motor performance. Therefore, cleaning the motor guarantees that internal parts operate smoothly and avoids additional damage.

LastlyStep 3: Component Repair and Replacement

Faulty components like burnt windings, worn bearings, or defective capacitors are replaced or repaired. Moreover, high-quality materials are used to ensure long-term performance and avoid frequent breakdowns.

Step 4: Lubrication and Reassembly

Lubrication minimizes friction and enables smooth motor operation. Subsequently, the motor is reassembled with care, ensuring all components are properly aligned for maximum performance.

Step 5: Final Testing and Calibration

Prior to returning the motor, we test it thoroughly to ensure that it operates efficiently without any defects. As a result, our quality tests ensure efficient and long-lasting motor performance.

Why Professional Electric Motor Repair?

Expertise and Experience

HK Appliances Repair Dubai has highly experienced technicians with years of experience in dealing with Electric motor problems in different appliances and industries. Our expertise ensures that each repair is carried out efficiently and effectively.

Cost-Effective Solutions

It’s cheaper to repair a damaged motor than to replace a whole appliance. Our fixes save customers money without compromising performance.

Energy Efficiency

A properly fixed Electric motor uses less power, saving on electricity bills and avoiding unnecessary wastage of energy. Effective motors optimize appliance performance and support sustainability.

Quick Turnaround Time

We know the need for speedy repair and make every effort to get our customers’ appliances up and running as soon as possible. Our speedy service reduces downtime and inconvenience.

Appliances That Need Electric Motor Repair

Air Conditioners

Electric motors drive fans and compressors in air conditioning equipment. When the motor is damaged, the cooling system is less efficient, and this causes discomfort and increased energy bills.

Washing Machines

Electric motors regulate spinning and agitation cycles. A faulty motor results in unbalanced loads, high noise, or total failures, necessitating immediate ac motor repair.

Refrigerators

Refrigerators utilize compressor motors to control temperature. A faulty motor leads to cooling issues, causing food spoilage and high energy bills

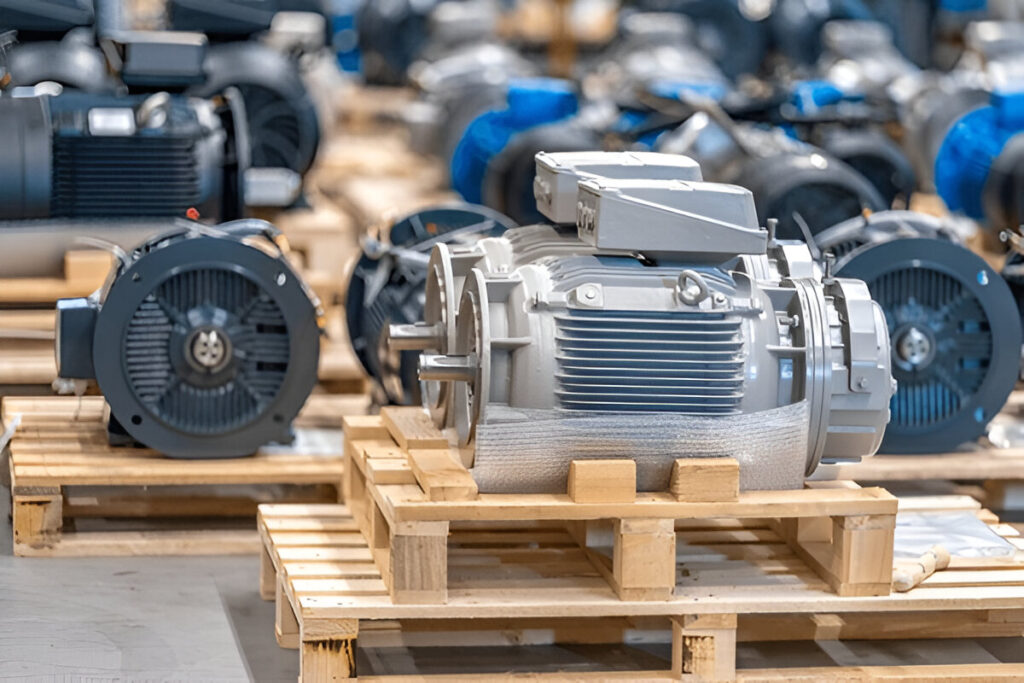

Industrial Machines

Electric motors are used in factories and workshops for numerous applications. Consequently, failure of these motors causes production disruptions and loss of money. Therefore, uninterrupted operations are ensured by proper maintenance.

Preventive Maintenance Tips for Electric Motors

Keep Motors Clean

Build-up of dirt and dust may clog ventilation and lead to overheating. Frequent cleaning is avoided by these problems.

Maintain a Stable Voltage Supply

Voltage fluctuations may cause windings damage and reduce the motor’s lifespan. Voltage stabilizers prevent electrical failure.

Lubricate Bearings Periodically

Proper lubrication minimizes friction and prolongs bearing life, avoiding costly premature wear and tear

Watch for Strange Noises or Vibrations

Strange noises or vibrations signal hidden motor problems. Early warning prevents expensive major repairs and replacements.

Plan Periodic Inspections

Periodic inspections by expert technicians aid in catching small faults before they become large-scale problems. Preventive maintenance is money-saving and guarantees long-term dependability.

Conclusion

Electric motor repair is an essential service that restores appliance functionality, reduces energy costs, and extends motor lifespan. At HK Appliances Repair Dubai, we provide expert repair solutions tailored to customer needs.

If your appliance motor is malfunctioning, contact us today for professional electric motor repair services. Our skilled technicians ensure efficient repairs, helping you avoid costly replacements. In conclusion, keep your appliances running smoothly with expert care and maintenance.